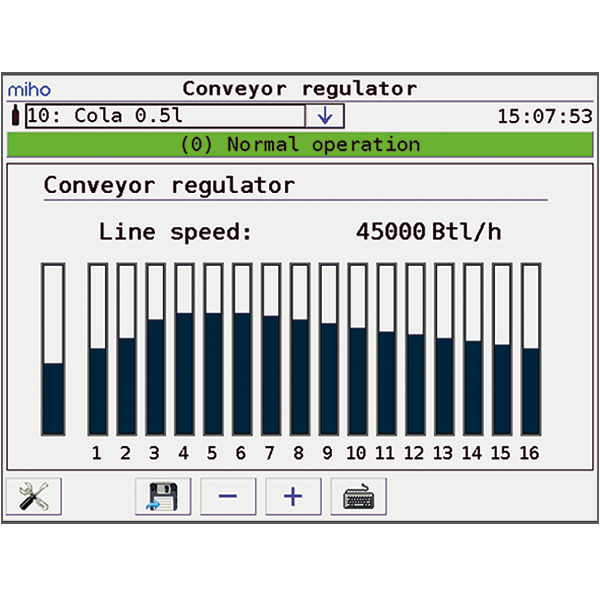

Conveyor control system

miho Pascal 2

Precisely and individual adjustable conveyor control to increase efficiency in the line: Optionally integrated as conveyor control in the David 2 empty bottle inspector.

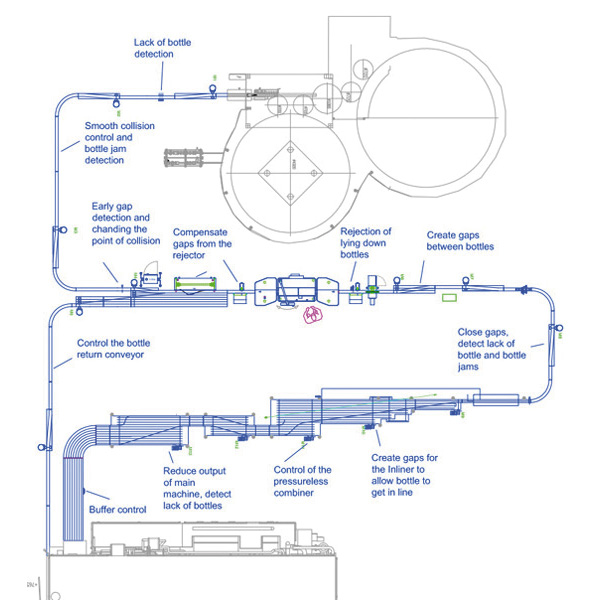

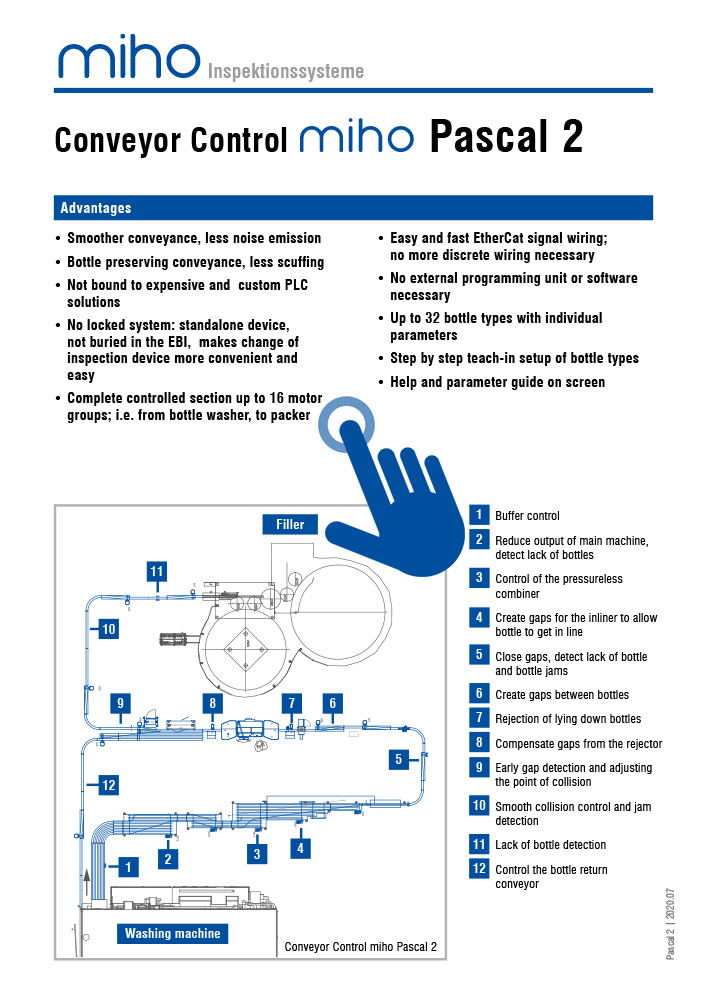

Electronic processor to control the areas of the buffer (static or dynamic), pressureless combiner or pressure inliner), one-lane blocking, closing bottle gaps, closing bottle gaps after rejection and creating the row of bottles in front of the lead machine. Millimetre-accurate measurement of container gaps for precise operation of the control system. This makes the transport of the containers quieter and gentler, and the Line itself becomes more efficient.

- Clear conveyor function of the inspection machine

- Detection of lag of bottles in the buffer area as well as at the infeed of the lead machine

- Possibilty to control a return conveyor after the Empty Bottle Inspection Machine , for example back to the Washing machine

Optional: Lying bottle detection via additional Light barriers and rejection via reject system

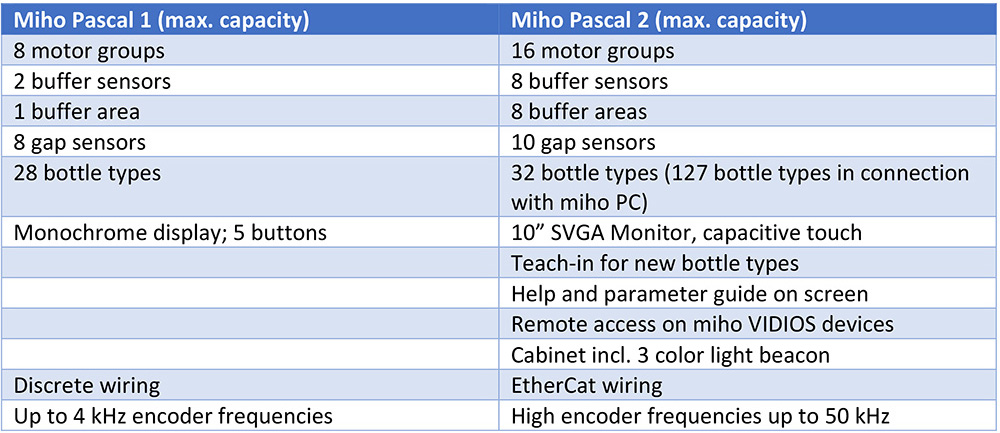

Up to 16 motor groups are available for the Pascal 2. And up to 32 programmable bottle types can be product-specifically parameterized.

The Pascal 2 has 10 sensor inputs available for detecting any deviating bottle divisions and 8 sensor inputs for the control of buffer conveyors.

The control module is located in a remote-control cabinet for operation at the conveyor belt and forms part of the scope of delivery.

Key benefits for users, service engineers

and sales representatives:

- Smoother conveyance, less noise emission

- Bottle preserving conveyance, less scuffing

- Not bound to expensive and custom PLC solutions

- No locked system: standalone device, not buried in the EBI, makes change of inspection device more convenient and easy

- Complete controlled section up to 16 motor groups; i.e. from bottle washer, to packer

- Easy and fast EtherCat signal wiring; no more discrete wiring necessary

- Step by step teach-in setup of bottle types with oscilloscope function

- No external programming unit or software necessary