Sealing inspection for PET

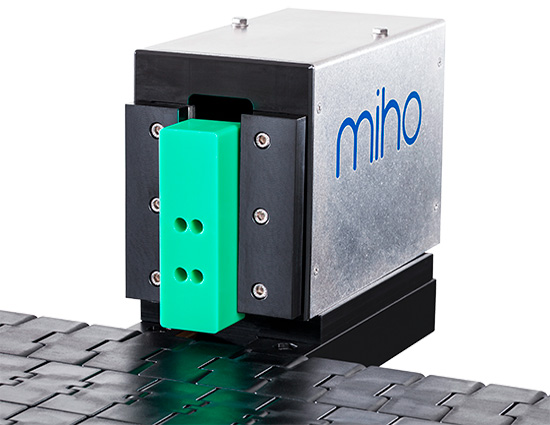

miho Feeler 2

Is the PET bottle sealed and leak-proof?

Device for use after the filler and capper to check the internal pressure of the container. A sensor wheel with sensor finger meassures the internal pressure without squeezing the bottle. Hygienic, as no leakage is forced.

To detect leaks, damage and/or control of nitrogen injection in plastic containers by, for e.g., non-sealing or slanting screw caps, missing or slanting sealing inserts, stress cracks or holes in the neck area (with CO2-content, medium or non-carbonated liquids). The tightness is checked by checking the internal pressure of the container using sensor fingers that are stored in a sensor wheel.

This results in a “direct” measurement of the internal pressure and there are no mechanical loads on the containers or on the machine, which can lead to wear and tear, damage or uncontrolled product leakage. Particularly with regard to a product leak, for e.g., for sugary, acidic products or products with solid components such as pulp, the Feeler is characterized by its great hygienic advantage here.