Label inspection miho EC-Cam

Product safety and flawless product appearance are getting more and more important to customers around the world. But not only is the appearance of the product at the point of sale is important, but also legal issues have to be taken into consideration. This especially accounts for production sites with an international range of customers. They often provide one product but with different labels in different languages and with different legal requirements for exportation. These labels are especially difficult to tell apart and mistakes are likely to happen. After all, we are just humans.

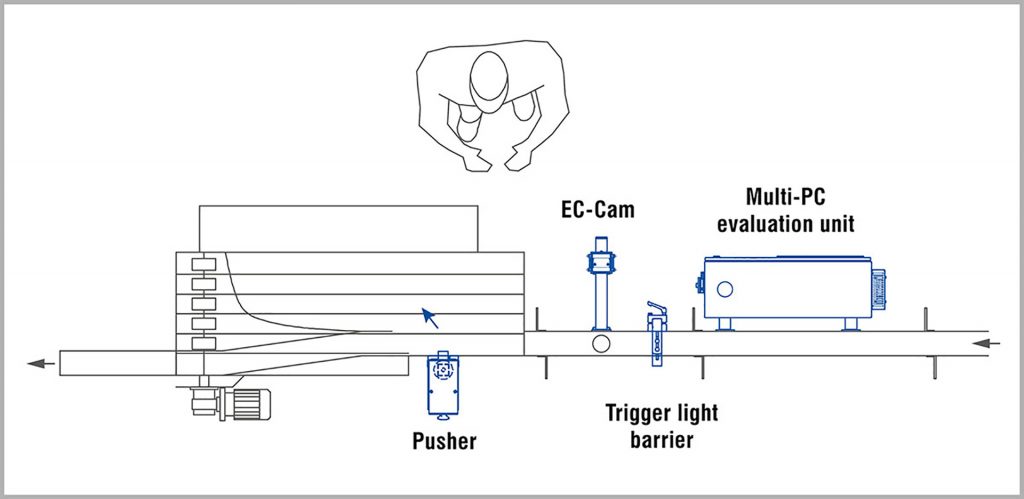

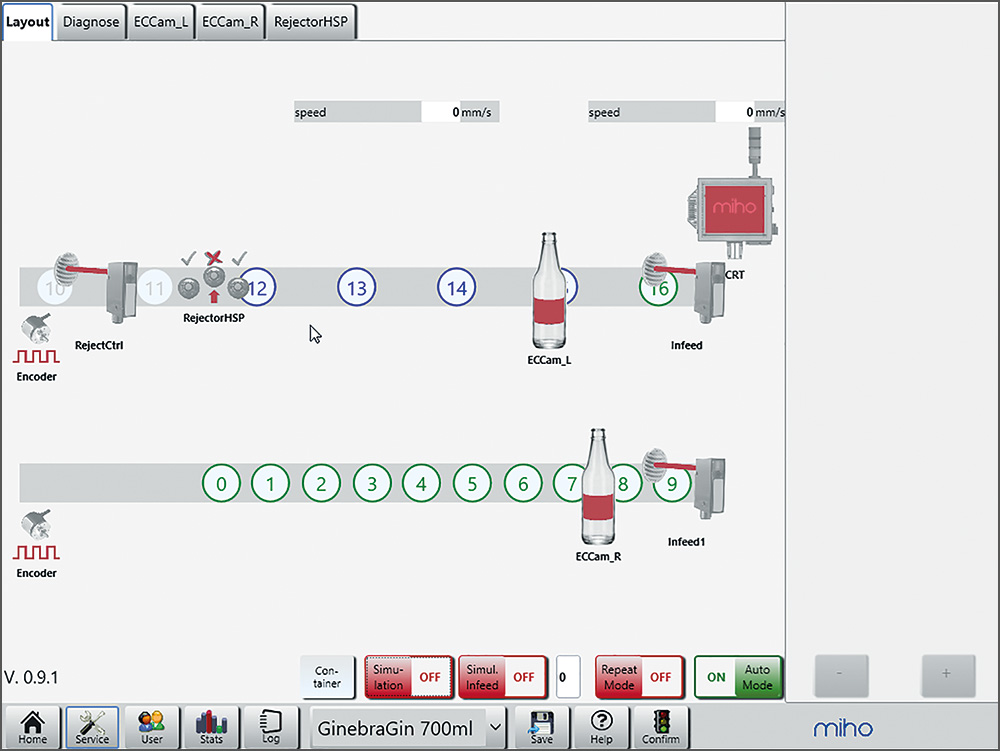

This is where the camera based label checking system miho EC-Cam steps in. This modular system can check not only the presence of labels, but also tells them apart from different varieties; checking on the integrity and the appearance of the label. All built into an existing labeler or on a single file conveyor; depending on the task. Moreover, the detection of print codes, such as best before dates, and Barcodes or 2D codes is possible.

These are your key-advantages

- Inspection of presence, position and slanted position

- Inspection of logical correctness

- Inspection of EAN barcode and expiry date imprint

- Single or multi camera setup, tailored to the task

- Integration in labeler or single file with aligned containers

- Easy teach-in mode with remote support

- Cost efficient integration of other miho devices such as fill level controls possible

Label checking systems in former times used simple light barriers that could only detect the presence of labels. Products of different colors or different container types would mostly result in additional light barriers to be installed while causing the performance of the system to decrease. Over the years, not only have the expectations of customers risen, but also the legal requirements, making label control essential. The indication of allergens, alcohol, sugar free products, as well as organic products are required, leading to severe legal consequences and to product recalls, if products are wrongly labeled. All around the world, these regulations are in effect.

As in Europe, with the regulation on provision of food information to consumers (EU 1169/2011), or similar regulations by the US American FDA and the British Retail Consortium BRC, most countries in the world have similar requirements of rightly labeled food and beverage.

Even a small mistake by an operator, putting the wrong labels in the labeling machine, or forgetting about the old ones in, can have a huge impact on the company, resulting in fines and product recalls, as well as a loss of image in the customer’s view. Furthermore, the labeling machine can cause labels to wrinkle or not be applied correctly or not at all. The ink jet or laser at the outfeed of the labeler is another possible source of failure, causing products without batch number or date code to hit the market.

For customers, these are the key advantages of installing an empty bottle inspector in the line:

- Less product recall, caused by glass fragments in the product

- Flawless product presentation at point of sale

- Increased line availability through less interruption by weak / broken containers

- Monitoring of the glassware quality and providing bad batch proof to the glass manufacturer

- Less waste of product, caused by leaking or damaged containers

All these failures can be recognized by the label control miho EC-Cam. The presence of a date code inked or laser printed on the product can also be inspected by the miho EC-Cam. This versatile piece of inspection equipment can be built into an existing or new labeling machine, as well as be attached to a single file conveyor in free flow, to check on aligned containers. The modular concept of the miho EC-Cam allows it to attach to one or more camera lighting units to the evaluation unit, tailored to your equipment and requirements. To gain more insight, please read our new technical bulletin on label inspection.

The camera and lighting modules are IP 67 rated and can inspect containers of a height up to 320 mm or possibly more. New label varieties can be implemented via an easy teach-in process by trained personnel, with the aid of miho remote services. The modular design of the miho EC-Cam allows it to be combined with a variety of other miho Products. For example our miho Newton fill height controls can be integrated in this system. The modern optical user interface and the implemented flow diagram of your line make operating the new OS miho Vidios SC easier than ever. This convenient system shows the operator help guidelines for container change over, failures and disturbance, leading to a fast and efficient process.